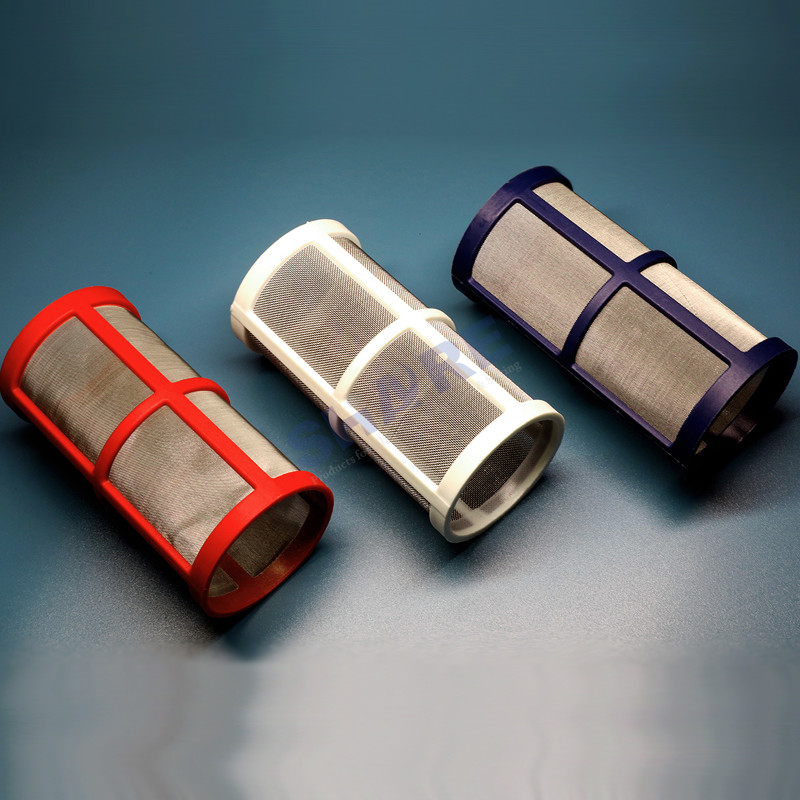

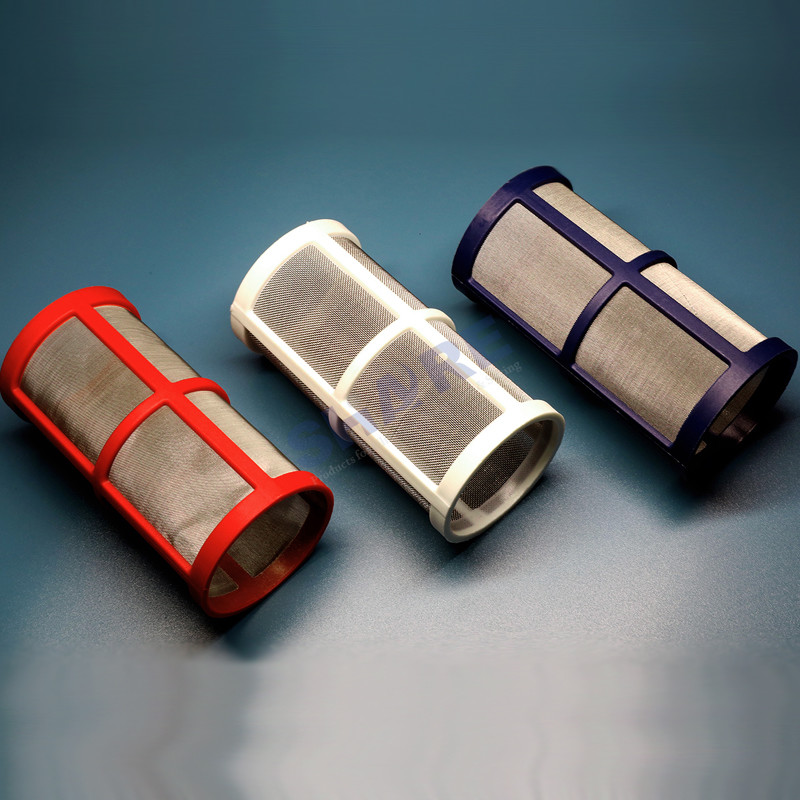

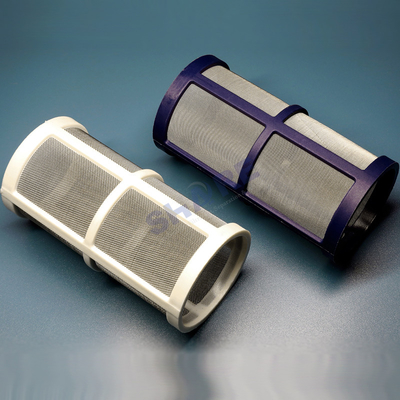

توضیحات محصول

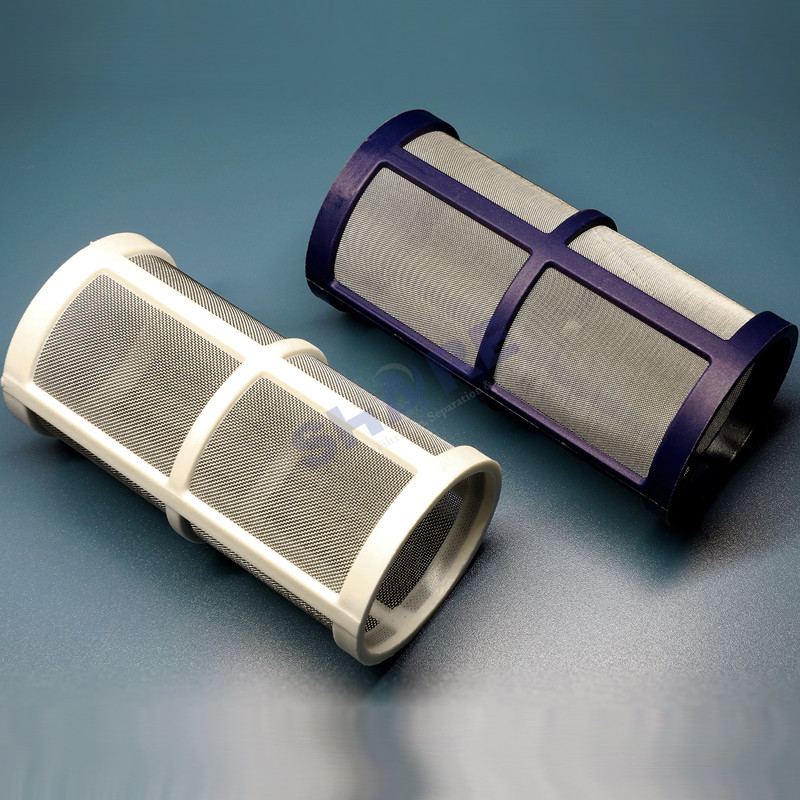

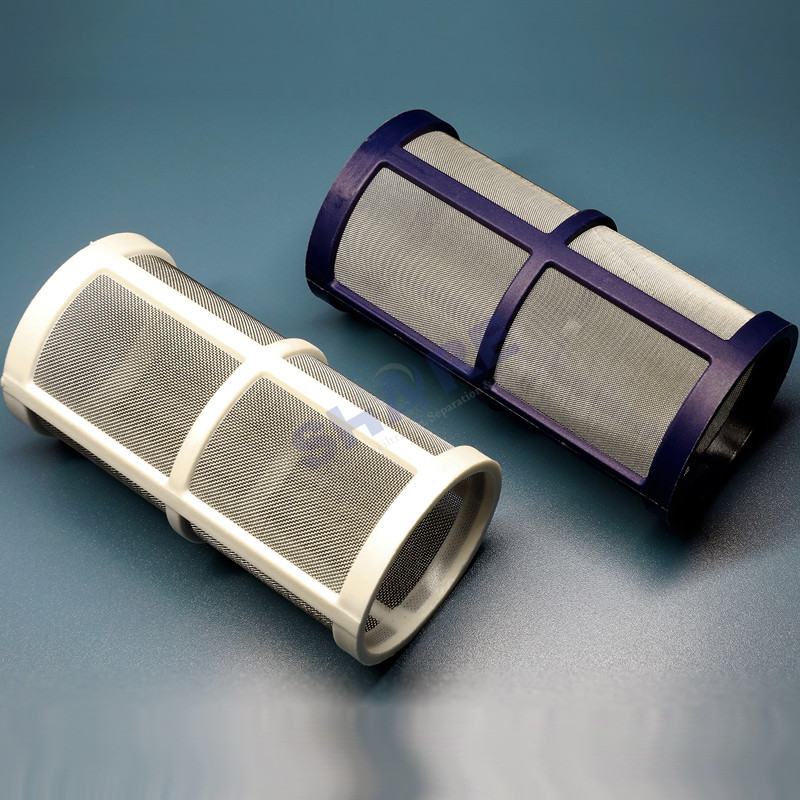

SHARE دارهبیش از 50 مجموعه ازدستگاه تزریق خودکار پلاستیکی عمودی و افقی برای برآورده کردن نیازهای مشتری و بازار برای راه حل های تصفیه عمومی و خاص.فیلترهای قالب بندی شده ما معمولا از انواع پلاستیک و میش ساخته شده اند.

فیلترهای قالب بندی شده ما با دوام طولانی، سبک و مقاوم در برابر خوردگی هستند، اغلب در لوازم خانگی، صنعت مواد غذایی، فیلتر آب، خودرو و کاربردهای پزشکی استفاده می شود.

مشتریان به راه حل های تصفیه SHARE برای سفارشی سازی، ردیابی کامل، عملکرد پایدار و قابل اعتماد و دقت دسته به دسته اعتماد می کنند.ما به مشتریان در هر مرحله از توسعه کمک می کنیم تا از قطعات فلتر با کیفیت بالا در قیمت رقابتی با تحویل سریع اطمینان حاصل کنیم.

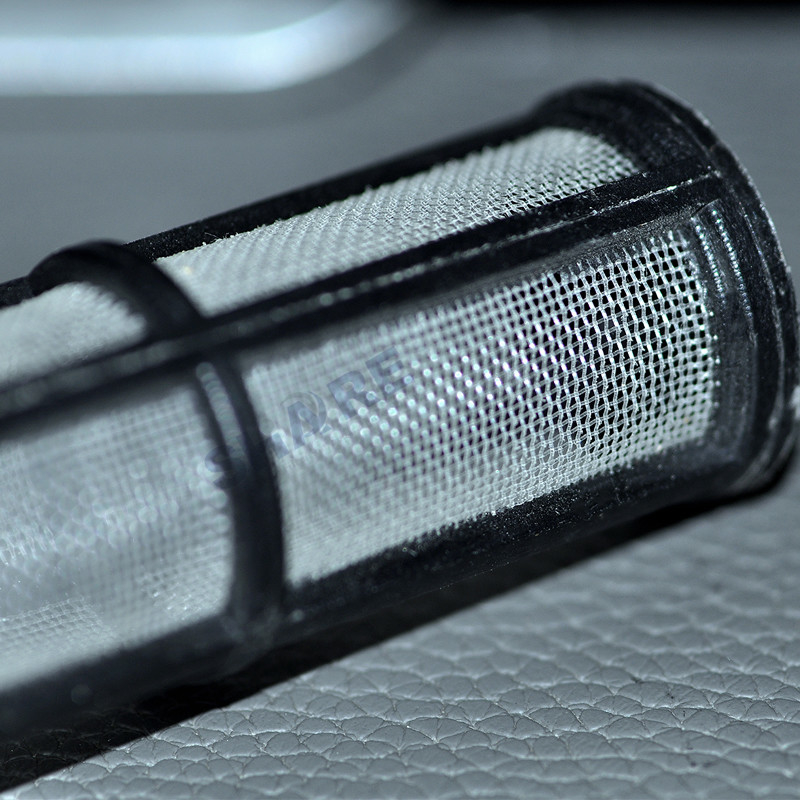

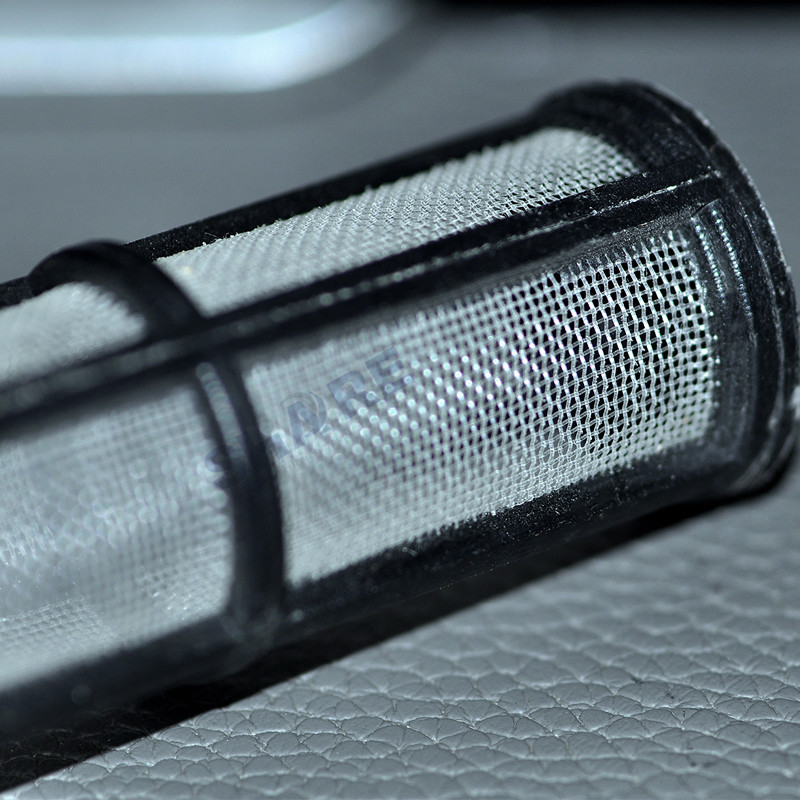

SHARE فیلتر لوله باغفیلتر فلتر رسوب است.کمک می کند تا از ماشین فشار و پمپ شما با فیلتر کردنسنگ، ذرات یا باقی ماندههمچنین برای خانوارانی که در مناطق دورافتاده، خانوارانی که آب چاه دارند و مزارع کوچک هستند ضروری است.

فیلتر لوله ما از شبکه با درجه بندی میکرو استفاده می کند80 100 130 200 300 500 um به عنوان یک فیلتر کهاجازه می دهد تا کوچکترین زباله ها را از منبع آب شما جذب کنید.برای تعویض، نگهداری و استفاده آسان است.

متخصص کاربرد ما بهترین راه حل های تصفیه از جمله مواد، درجه بندی های کوچک و طرح ها را برای شما بر اساس سالها تجربه و تخصص ما توصیه می کند.

براي تعويض لوله فيلتر شبكه اي در سايز هاي مختلف با ما تماس بگيريد.

| نام ماده |

صفحه فلتر لوله باغ |

| تولید کننده |

شرکت تایژو شار فلترز لمیتد |

| اندازه |

آداب |

| رنگ |

سیاه + قرمز + آبی + سبز + قهوه ای |

| درجه بندی میکرو |

80 100 130 200 300 500 امم |

| رتبه بندی میش |

200 155 120 80 50 30 چشم |

| برای |

فیلترهای نوع T و Y |

| مواد |

PCو شبکه فیلتر صفحه ((PA، PET، فولاد ضد زنگ و غیره) |

| تکنولوژی پردازش |

قالب گذاری |

| ویژگی ها |

• فیلترهای صفحه نمایش و دیسک همه کاره از پلی استر و فولاد ضد زنگ از 80 تا 500 میکروم برای پاسخگویی به طیف گسترده ای از نیازهای تصفیه

• صفحه نمایش ها و دیسک ها در برابر بیشتر مواد شیمیایی قابل مقاومت هستند

• مساحت فیلتر بزرگ و از دست دادن اصطکاک کم اجازه می دهد تا فواصل طولانی بین تمیز کردن

• عناصر دیسک و صفحه نمایش با کد رنگ قابل تعویض طیف گسترده ای از درجه تصفیه را فراهم می کنند

• ساخته شده از مواد مقاوم در برابر اشعه ی UV و با دوام برای مقاومت در برابر بدترین شرایط |

| درخواست |

اتصال به لوله باغ استاندارد، شیر آب خانگی یا ورودی ماشین فشار |

انتخاب مواد فیلتر برای عملکرد فیلترهای نهایی بسیار مهم است.

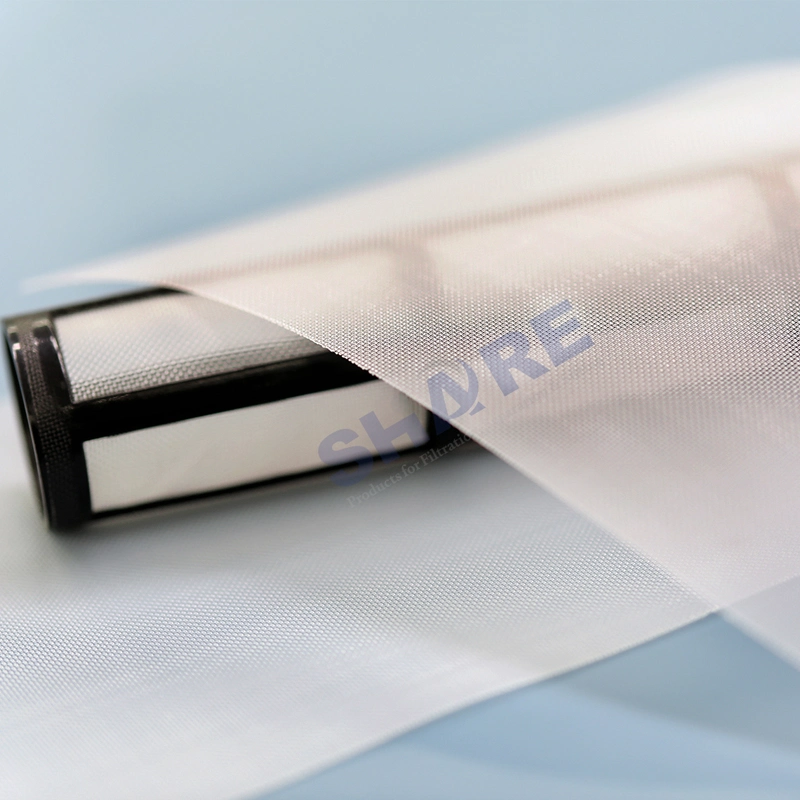

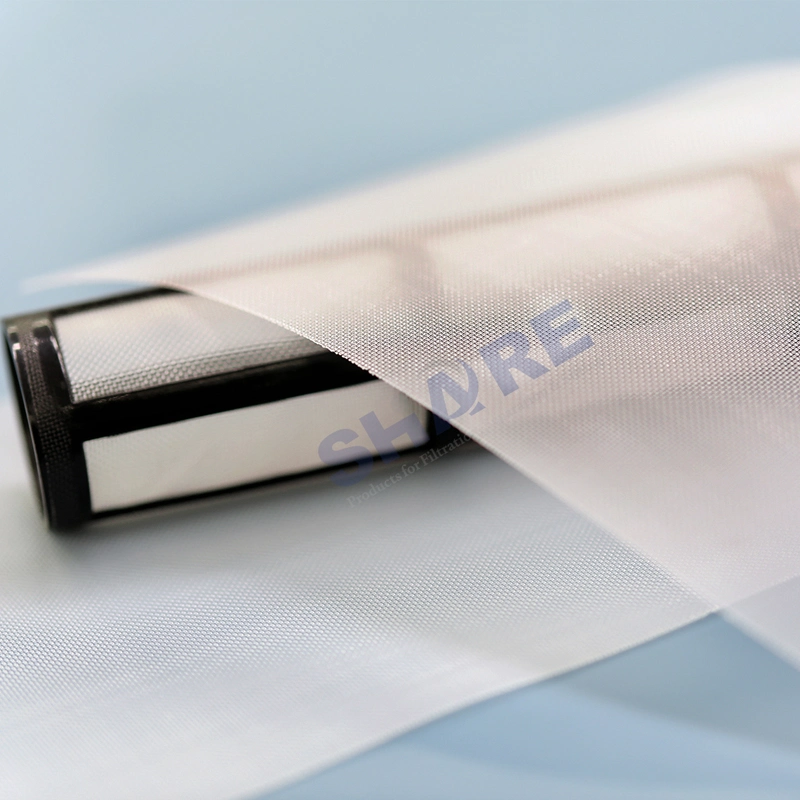

در SHARE، ما مواد فیلتر تولید می کنیمبا باز شدن دقیق میش، منطقه باز و ضخامت میش توسط خودمان مشخص می شود. رایج ترین مواد فیلتر برای فیلترهای پلاستیکی عبارتند از:

پلاسماسی (پلاسماسی): مقاومت در برابر اسید ها محدود است و به غلظت و درجه حرارت بستگی دارد. مقاومت عالی در برابر قلیات، از جمله سودا و پتاسای کاستیک.عملکرد شیمیایی در برابر حلال های آلی بسیار خوب استمقاومت در برابر دمای 0 تا 130 درجه سانتیگراد در حالت خشک و 95 تا 100 درجه سانتیگراد در آب

از پلی استر: مقاوم در برابر اکثر اسیدهای. مقاوم در برابر قلیات. مقاوم در برابر دمای -75 تا + 150 ° C (برای دوره های کوتاه مدت) ، تا 125 ° C برای نیازهای طولانی تر.

پی پی مچ: رزولوشن رطوبت در 95٪ رطوبت هوا و 25 ° C کمتر از 0.01٪ است. مقاومت در برابر قلیایی، حتی در غلظت های بالا. استفاده با حلال های آلی محدود است.مقاومت در برابر دما از 0 تا +150 °C (برای دوره های کوتاه مدت)، تا 125 °C برای نیازهای طولانی تر.

از فولاد ضد زنگ: بیشتر آلیاژ ها، 10 تا 2000 میکروم

فلزات دیگر: بیشتر آلیاژها از جمله اپوکسی و پوشش داده شده

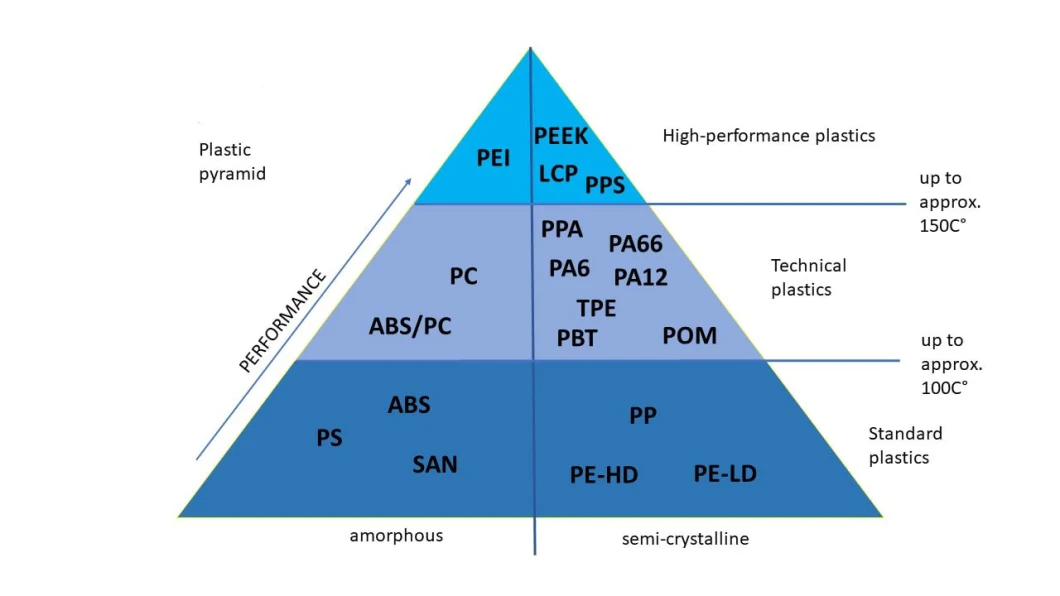

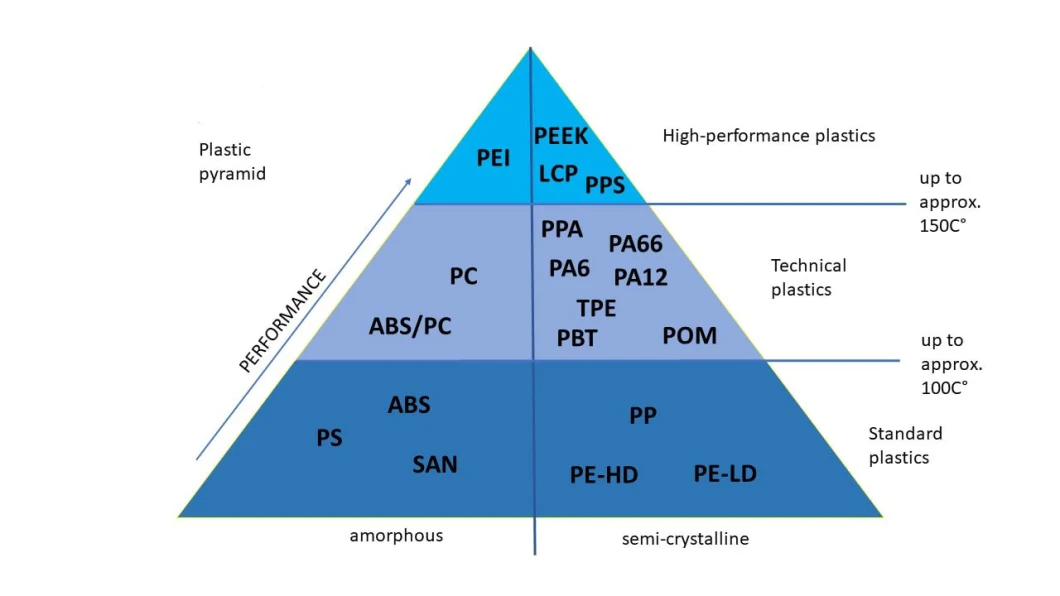

کاربرد و الزامات برای قطعات پلاستیکی قبل از قالب بندی تزریقی تعیین کننده است. پلاستیک های مورد استفاده اغلب ما از جمله PE، PP، ABS، PC، POM، PBT، PA، PPA به PEEK را انتخاب می کنیم.

مالکیت مواد یک دانش مهم برای قالب بندی تزریقی است. این به شدت با کیفیت قالب بندی، پایان و هزینه مرتبط است.تیم ما این دانش و تجربه را به محصولات قالب دهی مشتریان خود اختصاص می دهد. از انواع ترموپلاستیک (PA، PP، PC، POM، PET، ABS و Peek) تا ترموستات (PE،اپوکسی و سیلیکون) حتی مواد پلاستیکی ترکیبی (مانند فیبر شیشه ای)، ما ویژگی مواد را به عنوان یک ارزیابی ضروری در طراحی ابزار قرار می دهیم، بنابراین ما همچنین به پیشنهاد مواد معادل برای بهبود کیفیت یا کاهش هزینه کمک می کنیم.

اولین مرحله در ساخت محصولات قالب بندی شده تزریقی ایجاد قالب ها است. دقت این قالب ها بسیار مهم است زیرا به طور مستقیم بر کیفیت محصولات نهایی تأثیر می گذارد.اينطوري قالب ها رو درست ميکنيم:

1ما با بررسی نقشه های محصول شروع می کنیم.

2سپس، ما یک گزارش "طراحی برای تولید" (DFM) ایجاد می کنیم.

3بعد از آن، ما از تجزیه و تحلیل جریان قالب برای برنامه ریزی طراحی قالب استفاده می کنیم.

4ما نقشه های دقیق ابزار را می سازیم.

5. بالاخره، قالب رو درست میکنیم

وقتی قالب آماده شد، چند نمونه آزمایشی تولید می کنیم تا بررسی کنیم آیا آنها با ابعاد مناسب مطابقت دارند. اگر این طور باشد، این نمونه ها را برای تایید به مشتریان می فرستیم. اگر مشکلی وجود داشته باشد،ما قالب یا تنظیمات تولید را تنظیم می کنیم و نمونه های جدیدی را برای آزمایش ایجاد می کنیم.

بعد از اينکه مشتري ما نمونه ها رو تاييد کرد، ما به خريد مواد اوليه و بررسي کيفيت ادامه ميديمبا چک های چندگانه کیفیت در طول راه. در نهایت، ما سفارش را جمع می کنیم و بسته بندی می کنیم. وقتی همه چیز آماده است، ما یک لیست بسته بندی را با مشتریان برای هماهنگی محموله ها به اشتراک می گذاریم.

در سال 1983 تاسیس شد، Taizhou Share Filters Co. Ltd. در تولید پارچه های فیلتر تک رشته ای و چند رشته ای و اجزای فیلتر از پلی آمید، پلی استر،پلی پروپیلن، پلی اتیلن و شبکه فلزی.

با 40 سال تخصص و تجربه از مواد میش فیلتر دقیق به قطعات فیلتر، SHARE توانایی متناسب کردن محصولات ما به برنامه دقیق خود را از طریق ما برجسته تولید توانایی ها وفرآیند های ساخت خودکار ((کوتش، کالاندر، جوش، برش، خیاط، پیچ و خم، قالب بندی و غیره).

محصولات فیلتر ما در طیف گسترده ای از زمینه های مختلف فیلتر مانند استفاده می شودصنعت ولوازم خانگی، خودرو، آبیاری، هیدرولیک، پزشکی و بهداشت، مواد غذایی و نوشیدنی، الکترونیک و هوافضا،همراه با بسیاری از کاربردهای صنعتی دیگر.

با ادغام عمودی زنجیره تامین جهانی و تخصص ما، امکانات گسترده تولید و تولید ما، تجربیات ما در تیم تصفیه، و همچنین مدیریت مواد ما،ما کنترل تمام مراحل فرآیند تولید را از انتها به انتها انجام می دهیمتوانایی ما برای تولید محصولات به طور کارآمد نه تنها کیفیت محصول را تضمین می کند بلکه یک زنجیره تامین ثابت را نیز حفظ می کند.کاهش هزینه های تولید و کوتاه کردن زمان تحویل برای مشتریان ما.

این که آیا می خواهید کیفیت فلتر موجود خود را بهبود بخشید یا هزینه آن را کاهش دهید، برنامه ریزی یک برنامه فیلتر سازی جدید، یا نیاز به کمک در مورد مشخصات و تأیید طراحی،SHARE براي شما اينجاستمهارت های تخصصی ما در حل مشکلات آماده است تا به هر چالش ای که با آن مواجه می شوید، پاسخ دهد.

وقتی که ما دریافت کنیمچاپ، مشخصات، نقشه، نمونه یا محیط کاربردی شما،فروش ما با تجربه و مهندسان برنامه ریزی ارزیابی و سفارشی فیلترهای پلاستیکی گام به گام با توجه به اطلاعات ارائه شدهقبل از اینکه شروع به تولید فیلترهای قالب بندی شده شما کنیم، عوامل اصلی که در نظر می گیریم عبارتند از:

1اندازه میش یا اندازه ذرات شما نیاز به فیلتر

2مواد شبکه و مواد محفظه (وضعیت کار را در نظر بگیرید)

3قطر رشته ی میش، ضخامت میش، منطقه ی باز

4سازگاری شیمیایی: محفظه و شبکه فیلتر، حلال های کاستیک، اسیدی، آلی و غیره

5شرایط عملیاتی: دمای، کاهش فشار، جریان و غیره

6اتصال فیزیکی: برای نصب و تعویض آسان

هدف ما ارائه مطمئن ترین و مقرون به صرفه ترین راه حل های فیلتر برای تمام برنامه های تصفیه است.متخصصین برنامه های SHARE با دهه ها تجربه به شما کمک می کنند بهترین راه حل فیلتر را برای برنامه خود انتخاب کنید.

برای اطلاعات بیشتر و چگونگی کمک به شما در مورد نیازهای فیلتر سازی خاص خود، امروز با SHARE تماس بگیرید.

1بسته بندی شده در کیسه های PE مهر و موم شده، 10pcs به 500pcs / کیسه با توجه به اندازه واقعی، دو بار بسته بندی شده و برچسب محصول در کیسه داخلی متصل می شود

2. تو کیسه ی بزرگتر PE و بعد کارتونی استاندارد صادرات

3. بسته بندی کارتونی بیرونی با فیلم کشش PE برای جلوگیری از آسیب در طول حمل و نقل

4کمربند بسته بندی تقویت می شود اگر پالت ها در دسترس باشند

برچسب حاوی اطلاعات استاندارد زیر است:

نام محصول، سازنده، ماده، ابعاد، تاریخ تولید، شماره سفارش، شماره دسته و غیره.

| |

از پورت به پورت |

از در به در |

| اکسپرس ((DHL، UPS، FEDEX، EMS) |

|

1 تا 5 روز |

| حمل و نقل هوایی |

1 تا 5 روز |

4 تا 10 روز |

| حمل و نقل دریایی ((FCL) |

15 تا 30 روز |

20 تا 35 روز |

| حمل و نقل دریایی ((LCL) |

15 تا 30 روز |

۲۲ تا ۳۷ روز |

1کارخانه شما کجاست؟ چطور ميتونم اونجا رو ببينم؟

ما در شهر تایژو، استان ژجیانگ چین هستیم. با قطار، ما یک ساعت از هانژو و دو ساعت از شانگهای فاصله داریم.

2ميشه نمونه هاي مجاني بگيرم و چقدر طول ميکشه که اونا رو تحویل بدي؟

ما خوشحالیم که نمونه های رایگان را برای ارزیابی شما فراهم کنیم که به شما ارسال می شوددر عرض 2لطفاً برای نمونه ها با ما تماس بگیرید.

3چند وقت طول مي کشه تا يه نقل قول داشته باشي؟

در بیشتر موارد، ما در2اگه چيزي در RFQ بايد تاييد بشه، به زودي بهتون اطلاع ميديم

4چقدر زود ميتونم سفارشم رو تموم کنم؟

زمان تولید بستگی به مقدار دارد.5 تا 15تا زماني که شما سفارش را داده باشيد

5کنترل کیفیتتون چطوره؟

از طریق بازرسی بصری، تجهیزات حساس به فشار و تجهیزات بازرسی تصویری سه بعدی خودکار، اپراتورهای تولید ما در هر مرحله از فرآیند خود بازرسی انجام می دهند.علاوه بر این، ما بازرسی های نقطه ای و بازرسی های نهایی را توسط تیم کنترل کیفیت (QC) انجام می دهیم.

6بزرگترين مزیت تو چيه؟

یکی از شایستگی های اصلی ما توانایی های تبدیل عالی ما از نخ بیش از بافت به مقالات تبدیل شده با تیم فنی حرفه ای و تضمین کیفیت و مدیریت برای بیش از30سال ها

7چه نوع شرايط پرداختي رو قبول مي کنيد؟

T/T و LC و بیشتر.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!